Feature Feature

- Backlash-zero coupling

- Exellently

endurable and rigid against high torsion

- Maintenance and repair

are unnecessary-lubrication is

also unrequired

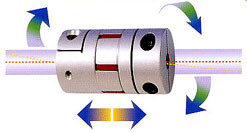

- An elastic spiter reduces the impact of a pit

load

|

Application examples Application examples

- Electric motor

- Position

control-positioning

- Robot system

- Direct drive of boring

and grinding machines

- Machining centers

- Medical

equipments

- Servomotors

- X-Y and X-Y-Z axial driving

|

|

|

|

A SJC-type coupling has such characterisics as

cannot be seen in other couplings owing to its perculiar construction.

It

means that the coupling has a complex feature that combines

characteristics of a backlash-zero metal spring coupling and those of a

coupling taking advantage of a common rubber elastic body.

Accordingly, a

SJC-type coupling is divided into 2 usages-one usage is the backlash-zero

method adopted in order to deliver the angle of rotation and another usage

is a method adopted in order to mainly deliver torque. Because each usage

has distinguished sleeves of different hardness, please choose a proper

coupling.

|

|

|

|

|

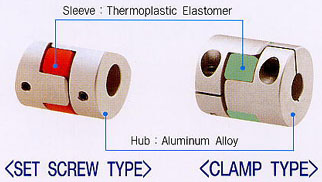

Sleeve

|

Attachment

|

|

Hardness

|

Color

|

SET SCREW

TYPE

|

CLAMP TYPE

|

|

92

|

Blue

|

SJC-☆☆-GR

|

SJC-☆☆-GR

|

|

98

|

Red

|

SJC-☆☆-RD

|

SJC-☆☆-RD

|

|

|

|

|

Selecting SJC Couplings Selecting SJC Couplings

|

|

A SJC-type coupling has such characterisics as

cannot be seen in other couplings owing to its perculiar construction.

It

means that the coupling has a complex feature that combines

characteristics of a backlash-zero metal spring coupling and

those of a

coupling taking advantage of a common rubber elastic body. Accordingly, a

SJC-type coupling is divided

into 2 usages-one usage is the backlash-zero

method adopted in order to deliver the angle of rotation and another usage

is

a method adopted in order to mainly deliver torque. Because each usage

has distinguished sleeves of different hardness,

please choose a proper

coupling.

|

|

|

|

|

|

In case of using a coupling within a low

torque sphere with an aim to mainly deliver the angle of rotation and

effect control,

the same backlash-zero characteristic as a metal spring

coupling offers can be utilized. In addition, it also has a function to

absorb a torsonal vibration that a common coupling cannot offer.

It

becomes less than the torque listed in the table. Please refer to the

table in the below.

Although the allowable torque usable as a

backlash-zero torque is same with the 2 kinds of sleeve, a sleeve,

a

sleeve of higher hardness can get the excellent performance in a use of

delivering the angle of rotation correctly.

|

|

|

2.

Torque Transmission 2.

Torque Transmission

|

|

A SJC-type coupling can be used for higher

torque than a metal coupling in that it delivers torque by way of

contracting the sleeve. Accordingly, it can be applied to a geneal

industrial machine such as a pump in no need of backlash-zero.

Although

the SJC-coupling are standardized in different sleeves, green sleeves of

lower hardness offer less usual torque

and maximum torque. While red

sleeves of higher hardness offer higher usual torque and maximum torque.

Thinking conversely, however, allowable value of mis-alignment is bigger

in the green sleeves and less in the red sleeves.

Please choose a proper

sleeve to fit your usage.

|

|

|

|

Product No.

|

Sleeve

Hardness

|

Zero Backlash

Permissible Torque

(N.m)

|

Rated

Torque

(N.m)

|

Max

Torque

(N.m))

|

Static Torsional

Stiffness

(N.m/rad)

|

Errors of

Eccentricity

(mm)

|

Errors of

Angularity

(°)

|

Errors of

Shaft End-Play

(mm)

|

|

SJC-14

|

GR

|

92

|

0.2

|

1.2

|

2.4

|

14

|

0.1

|

1.0

|

+0.6

0

|

|

RD

|

98

|

2

|

4

|

22

|

0.1

|

|

SJC-20

|

GR

|

92

|

0.2

|

3

|

6

|

29

|

0.15

|

1.0

|

+0.8

0

|

|

RD

|

98

|

3

|

6

|

29

|

0.15

|

|

SJC-25

|

GR

|

92

|

0.35

|

5

|

10

|

45

|

0.15

|

1.0

|

+1.0

0

|

|

RD

|

98

|

10

|

18

|

80

|

0.1

|

|

SJC-30

|

GR

|

92

|

0.5

|

7.5

|

15

|

73

|

0.15

|

1.0

|

+1.0

0

|

|

RD

|

98

|

12.5

|

25

|

130

|

0.1

|

|

SJC-40

|

GR

|

92

|

1.2

|

10

|

20

|

570

|

0.1

|

1.0

|

+1.2

0

|

|

RD

|

98

|

17

|

34

|

1200

|

0.1

|

|

SJC-55

|

GR

|

92

|

-

|

35

|

70

|

1600

|

0.15

|

1.0

|

+1.4

0

|

|

RD

|

98

|

60

|

120

|

2600

|

0.1

|

|

SJC-65

|

GR

|

92

|

-

|

95

|

190

|

3000

|

0.15

|

1.0

|

+1.5

0

|

|

RD

|

98

|

160

|

320

|

4900

|

0.1

|

|

SJC-80

|

GR

|

92

|

-

|

190

|

380

|

6500

|

0.1

|

1.0

|

+1.5

0

|

|

RD

|

98

|

320

|

640

|

11000

|

0.1

|

|

Product No.

|

A

|

L

|

W

|

B

|

C

|

F

|

M

|

Wrench

Torque

(N.m)

|

|

SJC-14 GR

|

14

|

7

|

22

|

6

|

1

|

3.5

|

M3

|

0.7

|

|

SJC-20 GR

|

20

|

10

|

30

|

8

|

1

|

5

|

M3

|

0.7

|

|

SJC-25 GR

|

25

|

10

|

32.5

|

9

|

1.25

|

5

|

M4

|

1.7

|

|

SJCA-30 GR

|

30

|

11

|

35

|

10

|

1.5

|

5.5

|

M4

|

1.7

|

|

SJCB-30 GR

|

30

|

15.8

|

44

|

10

|

1.5

|

7.7

|

M4

|

1.7

|

|

SJCA-40 GR

|

40

|

19.5

|

55

|

12

|

2

|

9

|

M5

|

4

|

|

SJCB-40 GR

|

40

|

25

|

66

|

12

|

2

|

11.5

|

M5

|

4

|

|

SJC-55 GR

|

55

|

30

|

78

|

14

|

2

|

14

|

M6

|

7

|

|

SJC-65 GR

|

65

|

35

|

90

|

15

|

2.5

|

17

|

M8

|

15

|

|

SJC-80 GR

|

80

|

45

|

114

|

18

|

3

|

22

|

M8

|

17

|

|

SJC-14 RD

|

14

|

7

|

22

|

6

|

1

|

3.5

|

M3

|

0.7

|

|

SJC-20 RD

|

20

|

10

|

30

|

8

|

1

|

5

|

M3

|

0.7

|

|

SJC-25 RD

|

25

|

10

|

32.5

|

9

|

1.25

|

5

|

M4

|

1.7

|

|

SJCA-30 RD

|

30

|

11

|

35

|

10

|

1.5

|

5.5

|

M4

|

1.7

|

|

SJCB-30 RD

|

30

|

15.8

|

44

|

10

|

1.5

|

7.7

|

M4

|

1.7

|

|

SJCA-40 RD

|

40

|

19.5

|

55

|

12

|

2

|

9

|

M5

|

4

|

|

SJCB-40 RD

|

40

|

25

|

66

|

12

|

2

|

11.5

|

M5

|

4

|

|

SJC-55 RD

|

55

|

30

|

78

|

14

|

2

|

14

|

M6

|

7

|

|

SJC-65 RD

|

65

|

35

|

90

|

15

|

2.5

|

17

|

M8

|

15

|

|

SJC-80 RD

|

80

|

45

|

114

|

18

|

3

|

22

|

M8

|

17

|

※ Download

CAD Files

|

Product No.

|

Max Bore

(mm)

|

Rated

Torque

(N.m)

|

Max

Torque

(N.m)

|

Max. Rotationa

Frequencyl

(min–1)

|

Moment

of Inertia

(kg.m²

|

Static Torsional

Stiffness

(N.m/rad)

|

Errors of

Eccentricity

(mm)

|

Errors of

Angularity

(°)

|

Errors of

Shaft End-Play

(mm)

|

Mass

(g)

|

|

SJC-14 GR

|

6.35

|

1.2

|

2.4

|

27000

|

2.1X10

|

14

|

0.1

|

1.0

|

+0.6

0

|

7.3

|

|

SJC-20 GR

|

9.252

|

3

|

6

|

19000

|

1.0X10

|

29

|

0.15

|

1.0

|

+0.8

0

|

18

|

|

SJC-25 GR

|

12

|

5

|

10

|

15000

|

2.4X10

|

45

|

0.15

|

1.0

|

+1.0

0

|

25

|

|

SJCA-30 GR

|

14

|

7.5

|

15

|

13000

|

5.9X10

|

73

|

0.15

|

1.0

|

+1.0

0

|

46

|

|

SJCB-30 GR

|

14

|

7.5

|

15

|

13000

|

7.2X10

|

73

|

0.15

|

1.0

|

+1.0

0

|

53

|

|

SJCA-40 GR

|

18

|

10

|

20

|

9600

|

3.1X10

|

570

|

0.1

|

1.0

|

+1.2

0

|

125

|

|

SJCB-40 GR

|

18

|

10

|

20

|

9600

|

4.0X10

|

570

|

0.1

|

1.0

|

+1.2

0

|

150

|

|

SJC-55 GR

|

25

|

35

|

70

|

7000

|

1.7X10

|

1600

|

0.15

|

1.0

|

+1.4

0

|

350

|

|

SJC-65 GR

|

30

|

95

|

190

|

5900

|

3.9X10

|

3000

|

0.15

|

1.0

|

+1.5

0

|

570

|

|

SJC-80 GR

|

40

|

190

|

380

|

4500

|

1.1X10

|

6500

|

0.1

|

1.0

|

+1.5

0

|

1150

|

|

SJC-14 RD

|

6.35

|

2

|

4

|

27000

|

2.1X10

|

22

|

0.1

|

1.0

|

+0.6

0

|

7.3

|

|

SJC-20 RD

|

9.252

|

5

|

10

|

19000

|

1.0X10

|

55

|

0.1

|

1.0

|

+0.8

0

|

18

|

|

SJC-25 RD

|

12

|

9

|

18

|

15000

|

2.4X10

|

80

|

0.1

|

1.0

|

+1.0

0

|

25

|

|

SJCA-30 RD

|

14

|

7.5

|

15

|

13000

|

5.9X10

|

73

|

0.15

|

1.0

|

+1.0

0

|

46

|

|

SJCB-30 RD

|

14

|

7.5

|

15

|

13000

|

7.2X10

|

73

|

0.15

|

1.0

|

+1.0

0

|

53

|

|

SJCA-40 RD

|

18

|

10

|

20

|

9600

|

3.1X10

|

570

|

0.1

|

1.0

|

+1.0

0

|

125

|

|

SJCB-40 RD

|

18

|

10

|

20

|

9600

|

4.0X10

|

570

|

0.1

|

1.0

|

+1.0

0

|

150

|

|

SJC-55 RD

|

25

|

60

|

120

|

7000

|

1.7X10

|

2600

|

0.1

|

1.0

|

+1.4

0

|

350

|

|

SJC-65 RD

|

30

|

160

|

320

|

5900

|

3.9X10

|

4900

|

0.1

|

1.0

|

+1.5

0

|

570

|

|

SJC-80 RD

|

40

|

320

|

640

|

4500

|

1.1X10

|

11000

|

0.1

|

1.0

|

+1.5

0

|

1150

|

|

Product No.

|

D1 - D2

|

|

3

|

4

|

4.5

|

5

|

6

|

6.35

|

7

|

8

|

9.525

|

10

|

11

|

12

|

14

|

15

|

16

|

18

|

19

|

20

|

25

|

26

|

28

|

30

|

35

|

|

SJC-14

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SJC-20

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SJC-25

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

|

|

|

|

SJC-30

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

|

|

SJC-40

|

|

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

|

|

SJC-55

|

|

|

|

|

|

|

|

|

|

|

|

●

|

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

SJC-65

|

|

|

|

|

|

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

SJC-80

|

|

|

|

|

|

|

|

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

Product No.

|

A

|

L

|

W

|

B

|

C

|

F

|

M

|

Wrench

Torque

(N.m)

|

|

SJC-14C GR

|

14

|

7

|

22

|

6

|

1

|

3.5

|

M2

|

0.5

|

|

SJC-20C GR

|

20

|

10

|

30

|

8

|

1

|

5

|

M2.6

|

1

|

|

SJC-25C GR

|

25

|

10

|

32.5

|

9

|

1.25

|

5

|

M3

|

1.8

|

|

SJCA-30C GR

|

30

|

11

|

35

|

10

|

1.5

|

5.5

|

M4

|

2.5

|

|

SJCB-30C GR

|

30

|

15.8

|

44

|

10

|

1.5

|

5.5

|

M4

|

2.5

|

|

SJCA-40C GR

|

40

|

19.5

|

55

|

12

|

2

|

6.7

|

M5

|

4

|

|

SJCB-40C GR

|

40

|

25

|

66

|

12

|

2

|

8.5

|

M5

|

4

|

|

SJC-55C GR

|

55

|

30

|

78

|

14

|

2

|

10.5

|

M6

|

8

|

|

SJC-65C GR

|

65

|

35

|

90

|

15

|

2.5

|

13

|

M8

|

16

|

|

SJC-80C GR

|

80

|

45

|

114

|

18

|

3

|

15

|

M8

|

20

|

|

SJC-14C RD

|

14

|

7

|

22

|

6

|

1

|

3.5

|

M2

|

0.5

|

|

SJC-20C RD

|

20

|

10

|

30

|

8

|

1

|

5

|

M2.6

|

1

|

|

SJC-25C RD

|

25

|

10

|

32.5

|

9

|

1.25

|

5

|

M3

|

1.8

|

|

SJCA-30C RD

|

30

|

11

|

35

|

10

|

1.5

|

5.5

|

M4

|

2.5

|

|

SJCB-30C RD

|

30

|

15.8

|

44

|

10

|

1.5

|

5.5

|

M4

|

2.5

|

|

SJCA-40C RD

|

40

|

19.5

|

55

|

12

|

2

|

6.7

|

M5

|

4

|

|

SJCB-40C RD

|

40

|

25

|

66

|

12

|

2

|

8.5

|

M5

|

4

|

|

SJC-55C RD

|

55

|

30

|

78

|

14

|

2

|

10.5

|

M6

|

8

|

|

SJC-65C RD

|

65

|

35

|

90

|

15

|

2.5

|

13

|

M8

|

16

|

|

SJC-80C RD

|

80

|

45

|

114

|

18

|

3

|

15

|

M8

|

20

|

|

Product No.

|

Max Bore

(mm)

|

Rated

Torque

(N.m)

|

Max

Torque

(N.m)

|

Max. Rotationa

Frequency

(min)

|

Moment

of Inertia

(kg.m²

|

Static Torsional

Stiffness

(N.m/rad)

|

Errors of

Eccentricity

(mm)

|

Errors of

Angularity

(°)

|

Errors of

Shaft End-Play

(mm)

|

Mass

(g)

|

|

SJC-14C GR

|

5

|

1.2

|

2.4

|

11000

|

1.6X10

|

14

|

0.1

|

1.0

|

+0.6

0

|

6

|

|

SJC-20C GR

|

8

|

3

|

6

|

7600

|

1.1X10

|

29

|

0.15

|

1.0

|

+0.8

0

|

19

|

|

SJC-25C GR

|

12

|

5

|

10

|

6200

|

2.4X10

|

45

|

0.15

|

1.0

|

+1.0

0

|

25

|

|

SJCA-30C GR

|

14

|

7.5

|

15

|

5100

|

6.2X10

|

73

|

0.15

|

1.0

|

+1.0

0

|

50

|

|

SJCB-30C GR

|

14

|

7.5

|

15

|

5100

|

7.5X10

|

73

|

0.15

|

1.0

|

+1.0

0

|

55

|

|

SJCA-40C GR

|

18

|

10

|

20

|

3800

|

3.1X10

|

570

|

0.1

|

1.0

|

+1.2

0

|

135

|

|

SJCB-40C GR

|

18

|

10

|

20

|

3800

|

3.9X10

|

570

|

0.1

|

1.0

|

+1.2

0

|

160

|

|

SJC-55C GR

|

25

|

35

|

70

|

2800

|

1.6X10

|

1600

|

0.15

|

1.0

|

+1.4

0

|

330

|

|

SJC-65C GR

|

30

|

95

|

190

|

2350

|

3.8X10

|

3000

|

0.15

|

1.0

|

+1.5

0

|

560

|

|

SJC-80C GR

|

40

|

190

|

380

|

1800

|

1.0X10

|

6500

|

0.1

|

1.0

|

+1.5

0

|

1050

|

|

SJC-14C RD

|

5

|

2

|

4

|

11000

|

1.6X10

|

22

|

0.1

|

1.0

|

+0.6

0

|

6

|

|

SJC-20C RD

|

8

|

5

|

10

|

7600

|

1.1X10

|

55

|

0.1

|

1.0

|

+0.8

0

|

19

|

|

SJC-25C RD

|

12

|

9

|

18

|

6200

|

2.4X10

|

80

|

0.1

|

1.0

|

+1.0

0

|

25

|

|

SJCA-30C RD

|

14

|

7.5

|

15

|

5100

|

6.2X10

|

73

|

0.15

|

1.0

|

+1.0

0

|

50

|

|

SJCB-30C RD

|

14

|

7.5

|

15

|

5100

|

7.5X10

|

73

|

0.15

|

1.0

|

+1.0

0

|

55

|

|

SJCA-40C RD

|

18

|

10

|

20

|

3800

|

3.1X10

|

570

|

0.1

|

1.0

|

+1.2

0

|

135

|

|

SJCB-40C RD

|

18

|

10

|

20

|

3800

|

3.9X10

|

570

|

0.1

|

1.0

|

+1.2

0

|

160

|

|

SJC-55C RD

|

25

|

60

|

120

|

2800

|

1.6X10

|

2600

|

0.1

|

1.0

|

+1.4

0

|

330

|

|

SJC-65C RD

|

30

|

160

|

320

|

2350

|

3.8X10

|

4900

|

0.1

|

1.0

|

+1.5

0

|

560

|

|

SJC-80C RD

|

40

|

320

|

640

|

1800

|

1.0X10

|

11000

|

0.1

|

1.0

|

+1.5

0

|

1050

|

|

Product No.

|

Stock Bores D1 - D2

|

|

3

|

4

|

4.5

|

5

|

6

|

6.35

|

7

|

8

|

9.525

|

10

|

11

|

12

|

14

|

15

|

16

|

18

|

19

|

20

|

25

|

26

|

28

|

30

|

35

|

|

SJC-14

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SJC-20

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SJC-25

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

|

|

|

|

SJC-30

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

|

|

SJC-40

|

|

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

|

|

|

|

SJC-55

|

|

|

|

|

|

|

|

|

|

|

|

●

|

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

|

|

SJC-65

|

|

|

|

|

|

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|

|

|

SJC-80

|

|

|

|

|

|

|

|

|

|

|

|

|

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

●

|

|