|

ZERO

BACKLASH DISK COUPLING

DISC COUPLING is a uni-body type which provides a

extensive twisting hardness and prominent mobility.

Disc coupling is a high precision coupling one can expect the

life-time longevity.

Disc Coupling is able to rotate with

high speed to a single direction or bidirectionally and is used

often mainly in high-precision measuring equipments, high speed

movement control systems, critical loads, dynameters

precision

encoders and etc.

Feature

Feature

- Designed for enduring high twisting

hardness

- No influence from backlash and providing long

life

- Accepting parallel, angular, shaft in-between

-

Single-and Double-Stage types

- Uni-body metal

structure

- Less inertia

爽

爽

- Servo motor, Stepping motor,

Precision motor

- High precision encoder, Dynamo drive

- High speed, high precision position control sytem

centrifugal separtor

- Copy machine, information &

Communication,

Audio products |

|

|

|

|

|

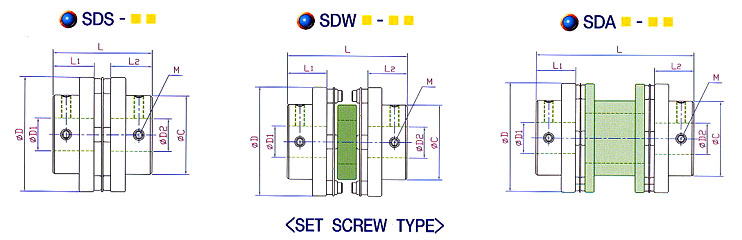

SDW,SDA

(SET SCREW TYPE)

|

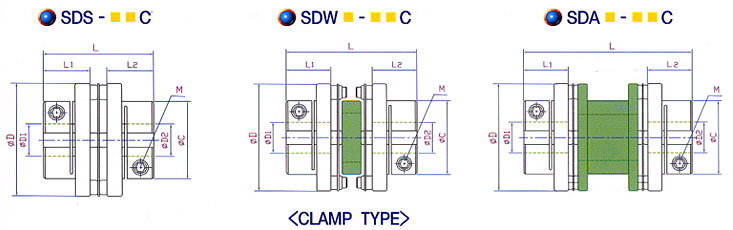

SDW-C,

SDA-C (CLAMP TYPE)

|

|

|

Product

No.

|

DIMENSION(±0.3)

|

Weight

(gr)

|

Rated

Torque

kgf-cm

|

Static

Torsional

Stiffness

Nm/rad

|

Max

RPM

min

|

Moment

of

Inertia

kgf-cm2

|

Max Misalignment

|

Stock

Bores

d1

d2

|

|

)D1

|

L1L2

|

L

|

M

|

Errors

of

Angularity

|

Errors

of

Eccentricity

|

Errors

of

Shaft End-Play

|

|

SDWA22

|

22.2

|

6.2

|

19.7

|

M3X2

|

16

|

10

|

400

|

15000

|

0.01/0.04

|

3°

|

0.25

|

0.5

|

)4~)6.35

|

|

SDWB22

|

22.2

|

6.2

|

22.2

|

M3X2

|

17

|

10

|

400

|

15000

|

0.012/0.05

|

3°

|

0.3

|

0.5

|

)4~)6.35

|

|

SDA22

|

22.2

|

6.2

|

28.2

|

M3X2

|

18

|

10

|

400

|

15000

|

0.013/0.05

|

3°

|

0.5

|

0.5

|

)4~)6.35

|

|

SDWA22C

|

22.2

|

8.6

|

24

|

M2.6

|

18

|

10

|

400

|

15000

|

0.013/0.05

|

3°

|

0.25

|

0.5

|

)4~)6.35

|

|

SDWB22C

|

22.2

|

8.6

|

26.4

|

M2.6

|

19

|

10

|

400

|

15000

|

0.013/0.032

|

3°

|

0.3

|

0.5

|

)4~)6.35

|

|

SDA22C

|

22.2

|

8.6

|

32.4

|

M2.6

|

20

|

10

|

400

|

15000

|

0.014/0.056

|

3°

|

0.5

|

0.5

|

)4~)6.35

|

|

SDWA26

|

26.6

|

7.3

|

25.5

|

M4X2

|

28

|

15

|

600

|

15000

|

0.023/0.11

|

3°

|

0.3

|

0.5

|

)5~)10

|

|

SDA26

|

26.6

|

7.3

|

31.2

|

M4X2

|

32

|

15

|

600

|

15000

|

0.032/0.13

|

3°

|

0.5

|

0.5

|

)5~)10

|

|

SDWA26C

|

26.6

|

10.7

|

32

|

M3

|

34

|

15

|

600

|

15000

|

0.034/0.14

|

3°

|

0.3

|

0.5

|

)5~)10

|

|

SDA26C

|

26.6

|

10.7

|

38

|

M3

|

39

|

15

|

600

|

15000

|

0.039/0.16

|

3°

|

0.5

|

0.5

|

)5~)10

|

|

SDWA31

|

31.8

|

7

|

23.8

|

M4X2

|

30

|

30

|

1300

|

15000

|

0.043/0.17

|

3°

|

0.25

|

0.5

|

)6~)14

|

|

SDWB31

|

31.8

|

7

|

28.6

|

M4X2

|

38

|

30

|

1300

|

15000

|

0.055/0.22

|

3°

|

0.3

|

0.5

|

)6~)14

|

|

SDA31

|

31.8

|

7

|

35.3

|

M4X2

|

38

|

30

|

1300

|

15000

|

0.055/0.22

|

3°

|

0.5

|

0.5

|

)6~)14

|

|

SDWA31C

|

31.8

|

11.6

|

33

|

M3

|

52

|

30

|

1300

|

15000

|

0.015/0.3

|

3°

|

0.25

|

0.5

|

)6~)14

|

|

SDWB31C

|

31.8

|

11.6

|

38

|

M3

|

60

|

30

|

1300

|

15000

|

0.087/0.35

|

3°

|

0.3

|

0.5

|

)6~)14

|

|

SDA31C

|

31.8

|

11.6

|

44.5

|

M3

|

60

|

30

|

1300

|

15000

|

0.087/0.35

|

3°

|

0.5

|

0.5

|

)6~)14

|

|

SDWA39C

|

39

|

13.6

|

39

|

M4

|

95

|

60

|

1,500

|

15000

|

0.21/0.85

|

3°

|

0.2

|

0.5

|

)6~)16

|

|

SDWC39C

|

39

|

13.6

|

44.8

|

M4

|

110

|

60

|

1,500

|

15000

|

0.24/1.0

|

3°

|

0.3

|

0.5

|

)6~)16

|

|

SDA39C

|

39

|

13.6

|

56.2

|

M4

|

120

|

60

|

1,500

|

15000

|

0.3/1.06

|

3°

|

0.4

|

0.5

|

)6~)16

|

|

SDWC42C

|

42.5

|

13.6

|

46

|

M4

|

120

|

75

|

1600

|

15000

|

0.32/1.28

|

3°

|

0.3

|

0.5

|

)8~)18

|

|

SDWC47C

|

47

|

16

|

49.6

|

M4

|

160

|

110

|

2000

|

15000

|

0.52/2.08

|

3°

|

0.4

|

0.5

|

)10~)19

|

|

SDWA54C

|

54

|

19

|

52

|

M5

|

250

|

230

|

2,600

|

10000

|

1.04/4.15

|

3°

|

0.3

|

0.5

|

)12~)25

|

|

SDWC54C

|

54

|

19

|

58

|

M5

|

280

|

230

|

2,600

|

10000

|

1.16/4.64

|

3°

|

0.4

|

0.5

|

)12~)25

|

|

|

|

|

Product

No.

|

DIMENSION(±0.3)

|

Weight

(gr)

|

Rated

Torque

kgf-cm

|

Static

Torsional

Stiffness

Nm/rad

|

Max

RPM

min

|

Moment

of

Inertia

kgf-cm2

|

Max Misalignment

|

Stock

Bores

d1

d2

|

|

D1

|

D2

|

L1L2

|

L

|

M

|

Errors

of

Angularity

|

Errors

of

Eccentricity

|

Errors

of

Shaft end-play

|

|

SDS42

|

42.5

|

29.2

|

13.5

|

30

|

M4

|

65

|

75

|

2800

|

15000

|

0.17(0.66)

|

1.5°

|

0

|

0.25

|

)6~)15

|

|

SDWA42

|

42.5

|

29.2

|

13.5

|

39

|

M4

|

84

|

75

|

1600

|

15000

|

0.21(0.85)

|

3°

|

0.25

|

0.5

|

)6~)15

|

|

SDWB42

|

42.5

|

29.2

|

13.5

|

44

|

M4

|

94

|

75

|

1600

|

15000

|

0.24(0.94)

|

3°

|

0.25

|

0.5

|

)6~)15

|

|

SDAA42

|

42.5

|

29.2

|

13.5

|

50.2

|

M4

|

105

|

75

|

2000

|

15000

|

0.27(1.05)

|

3°

|

0.5

|

0.5

|

)6~)15

|

|

SDAB42

|

42.5

|

29.2

|

13.5

|

57.5

|

M4

|

110

|

75

|

2000

|

15000

|

0.28(1.10)

|

3°

|

0.7

|

0.5

|

)6~)15

|

|

SDAC42

|

42.5

|

29.2

|

13.5

|

67

|

M4

|

115

|

75

|

2000

|

15000

|

0.29(1.15)

|

3°

|

1

|

0.5

|

)6~)15

|

|

SDS47

|

47

|

33

|

14

|

31

|

M5

|

91

|

110

|

3400

|

15000

|

0.27(1.12)

|

1.5°

|

0

|

0.25

|

)8~)19

|

|

SDWA47

|

47

|

33

|

14

|

39

|

M5

|

115

|

110

|

2000

|

15000

|

0.34(1.41)

|

3°

|

0.25

|

0.5

|

)8~)19

|

|

SDWB47

|

47

|

33

|

14

|

45

|

M5

|

120

|

110

|

2000

|

15000

|

0.36(1.48)

|

3°

|

0.4

|

0.5

|

)8~)19

|

|

SDAA47

|

47

|

33

|

14

|

57.5

|

M5

|

140

|

110

|

2850

|

15000

|

0.42(1.73)

|

3°

|

0.6

|

0.5

|

)8~)19

|

|

SDAB47

|

47

|

33

|

14

|

84

|

M5

|

160

|

110

|

2850

|

15000

|

0.47(1.98)

|

3°

|

1.4

|

0.5

|

)8~)19

|

|

SDS54

|

54

|

38.5

|

19

|

42

|

M5

|

130

|

230

|

4800

|

15000

|

0.49(1.96)

|

1.5°

|

0

|

0.25

|

)10~)20

|

|

SDWA54

|

54

|

38.5

|

19

|

55

|

M5

|

177

|

230

|

2800

|

15000

|

0.67(2.67)

|

3°

|

0.25

|

0.5

|

)10~)20

|

|

SDAA54

|

54

|

38.5

|

19

|

70

|

M5

|

230

|

230

|

4000

|

15000

|

0.88(3.45)

|

3°

|

0.7

|

0.5

|

)10~)20

|

|

SDAB54

|

54

|

38.5

|

19

|

84

|

M5

|

250

|

230

|

4000

|

15000

|

1.04(4.15)

|

3°

|

1.2

|

0.5

|

)10~)20

|

|

SDS64

|

64

|

48

|

26

|

58

|

M8

|

292

|

310

|

6000

|

15000

|

1.72(6.94)

|

1.5°

|

0

|

0.25

|

)12~)28

|

|

SDWA64

|

64

|

48

|

26

|

41.2

|

M8

|

373

|

310

|

4100

|

15000

|

2.2(8.8)

|

3°

|

0.4

|

0.5

|

)12~)28

|

|

SDA64

|

64

|

48

|

26

|

89.2

|

M8

|

450

|

310

|

5200

|

15000

|

2.66(10.62)

|

3°

|

0.9

|

0.5

|

)12~)28

|

|

|

|

Product

No.

|

DIMENSION(±0.3)

|

Weight

(gr)

|

Rated

Torque

kgf-cm

|

Static

Torsional

Stiffness

Nm/rad

|

Max

RPM

min

|

Moment

of

Inertia

kgf-cm2

|

Max Misalignment

|

Stock

Bores

d1

d2

|

|

D1

|

D2

|

L1L2

|

L

|

M

|

Errors

of

angularity

|

Errors

of

eccentricity

|

Errors

of

Shaft

end-play

|

|

SDS42C

|

42.5

|

29.2

|

13.5

|

30

|

M3

|

65

|

75

|

2800

|

15000

|

0.17(0.66)

|

1.5°

|

0

|

0.25

|

)6~)15

|

|

SDWA42C

|

42.5

|

29.2

|

13.5

|

39

|

M3

|

84

|

75

|

1600

|

15000

|

0.21(0.85)

|

3°

|

0.25

|

0.5

|

)6~)15

|

|

SDWB42C

|

42.5

|

29.2

|

13.5

|

44.6

|

M3

|

84

|

75

|

1600

|

15000

|

0.24(0.94)

|

3°

|

0.35

|

0.5

|

)6~)15

|

|

SDAA42C

|

42.5

|

29.2

|

13.5

|

50

|

M3

|

105

|

75

|

2000

|

15000

|

0.27(1.05)

|

3°

|

0.5

|

0.5

|

)6~)15

|

|

SDAB42C

|

42.5

|

29.2

|

13.5

|

57.5

|

M3

|

110

|

75

|

2000

|

15000

|

0.28(1.10)

|

3°

|

0.7

|

0.5

|

)6~)15

|

|

SDAC42C

|

42.5

|

29.2

|

13.5

|

67

|

M3

|

115

|

75

|

2000

|

15000

|

0.29(1.15)

|

3°

|

1

|

0.5

|

)6~)15

|

|

SDS47C

|

47

|

33

|

17

|

37.2

|

M4

|

108

|

110

|

3400

|

15000

|

0.32(1.33)

|

1.5°

|

0

|

0.25

|

)8~)19

|

|

SDWA47C

|

47

|

33

|

17

|

45

|

M4

|

120

|

110

|

2000

|

15000

|

0.361.48)

|

3°

|

0.25

|

0.5

|

)8~)19

|

|

SDWB47C

|

47

|

33

|

17

|

51

|

M4

|

132

|

110

|

2000

|

15000

|

0.39(1.63)

|

3°

|

0.4

|

0.5

|

)8~)19

|

|

SDAA47C

|

47

|

33

|

17

|

63.5

|

M4

|

152

|

110

|

2850

|

15000

|

0.45(1.87)

|

3°

|

0.6

|

0.5

|

)8~)19

|

|

SDAB47C

|

47

|

33

|

17

|

89.6

|

M4

|

172

|

110

|

2850

|

15000

|

0.51(2.12)

|

3°

|

1.4

|

0.5

|

)12~)19

|

|

SDS54C

|

54

|

38.5

|

21.5

|

47

|

M5

|

145

|

230

|

4800

|

15000

|

0.55(2.19)

|

1.5°

|

0

|

0.25

|

)10~)20

|

|

SDW54C

|

54

|

38.5

|

21.5

|

60

|

M5

|

192

|

230

|

2600

|

15000

|

0.72(2.88)

|

3°

|

0.25

|

0.5

|

)10~)20

|

|

SDAA54C

|

54

|

38.5

|

21.5

|

75

|

M5

|

240

|

230

|

3900

|

15000

|

0.90(3.6)

|

3°

|

0.7

|

0.5

|

)10~)20

|

|

SDAB54C

|

54

|

38.5

|

21.5

|

88.9

|

M5

|

266

|

230

|

3900

|

15000

|

1.1(4.4)

|

3°

|

1.1

|

0.5

|

)10~)20

|

|

SDS64C

|

64

|

48

|

26

|

58

|

M6

|

292

|

310

|

6000

|

15000

|

1.72(6.94)

|

1.5°

|

0

|

0.3

|

)12~)28

|

|

SDW64C

|

64

|

48

|

26

|

74

|

M6

|

373

|

310

|

4100

|

15000

|

2.2(8.80)

|

3°

|

0.4

|

0.3

|

)12~)28

|

|

SDA64C

|

64

|

48

|

26

|

89.2

|

M6

|

450

|

310

|

5000

|

15000

|

2.66(10.62)

|

3°

|

0.9

|

0.6

|

)12~)28

|

|

SDS80C

|

79

|

79

|

30

|

66.5

|

M8

|

800

|

680

|

13000

|

7000

|

7.47(29.8)

|

1.5°

|

0

|

0.25

|

)15~)35

|

|

SDW80C

|

79

|

79

|

30

|

82

|

M8

|

900

|

680

|

12000

|

7000

|

8.4(33.6)

|

3°

|

0.3

|

0.5

|

)15~)35

|

|

SDA80C

|

79

|

79

|

30

|

98

|

M8

|

1000

|

680

|

13000

|

7000

|

9.33(37.33)

|

3°

|

0.5

|

0.5

|

)15~)35

|

|